Peliou New Materials Technology Co.,LTD

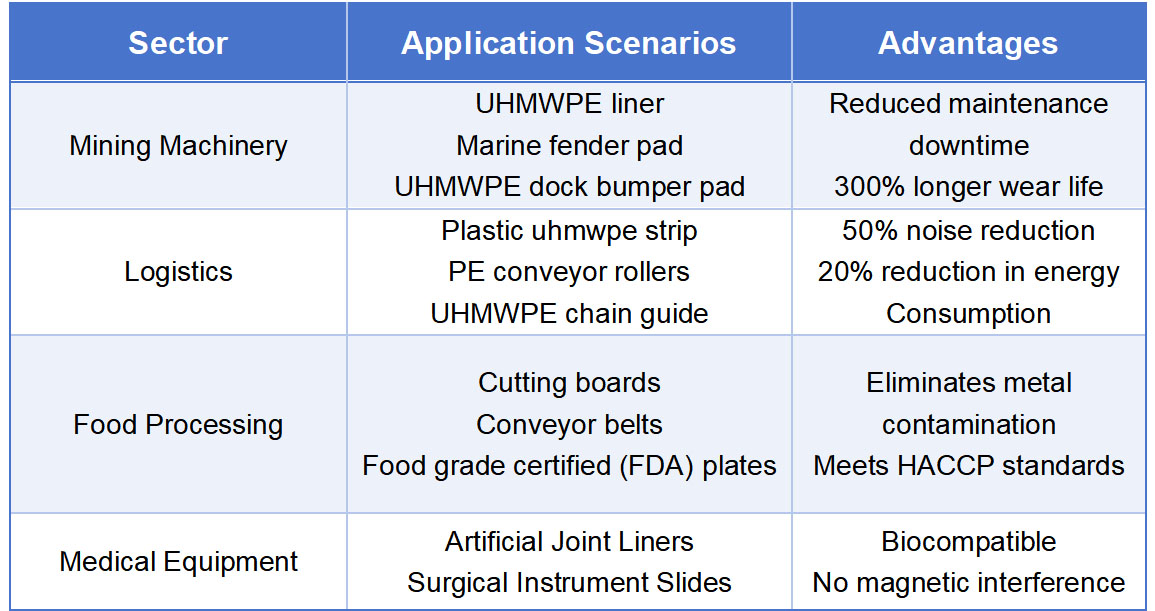

Application outrigger pad , pe ground mat , synthetic ice rink , lining boards , Marine fender pads , CNC machining parts ,

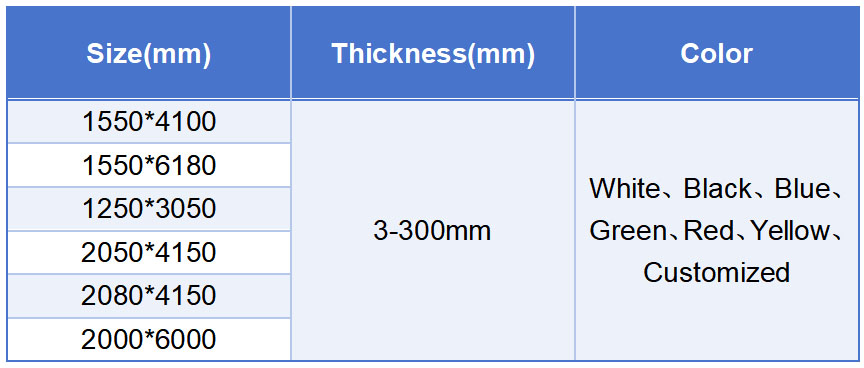

Key Features Size: 1550mmx4100mm

2000mmx4000mm

1000mmx3000mm

2000mmx6000mm

Colour: common white and black, other colors can be customized

Customization:Size can be customized to customer requirements change.

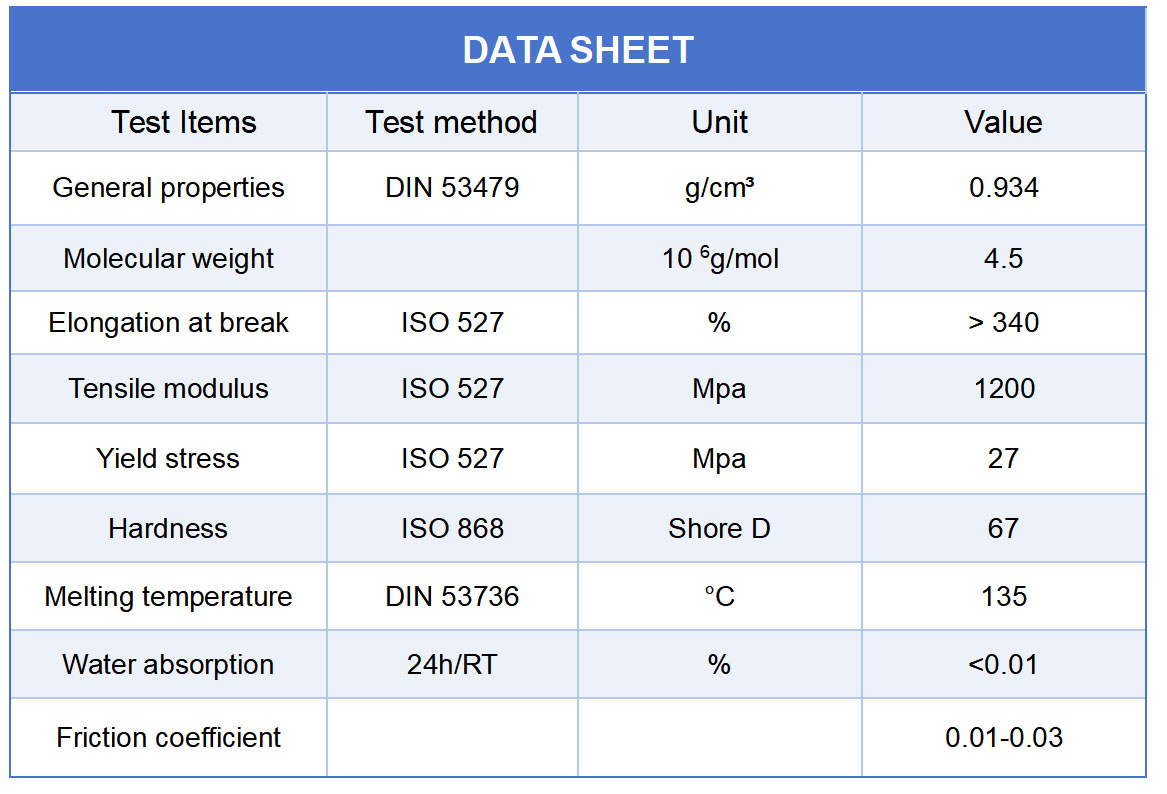

Overview UHMW PE is used where sliding abrasion occurs or where metal parts meet, causing friction or abrasion wear. It is excellent for chute and hopper liners, convey or components, wear pads, machine guides, impact surface and guide rails.

;

Previous: Temporary Road Mats Next: Back List

ODM & OEM

UHMWPE, HDPE, PP, Nylon, ABS and any Material

Customized Packaging

Graphic customization

Size & Color custom