Peliou New Materials Technology Co.,LTD

In industrial applications, the choice of material depends on a balance between performance, cost and durability. Traditionally, steel has dominated areas such as construction and machinery, while UHMWPE is emerging as a superior alternative. Below is a c

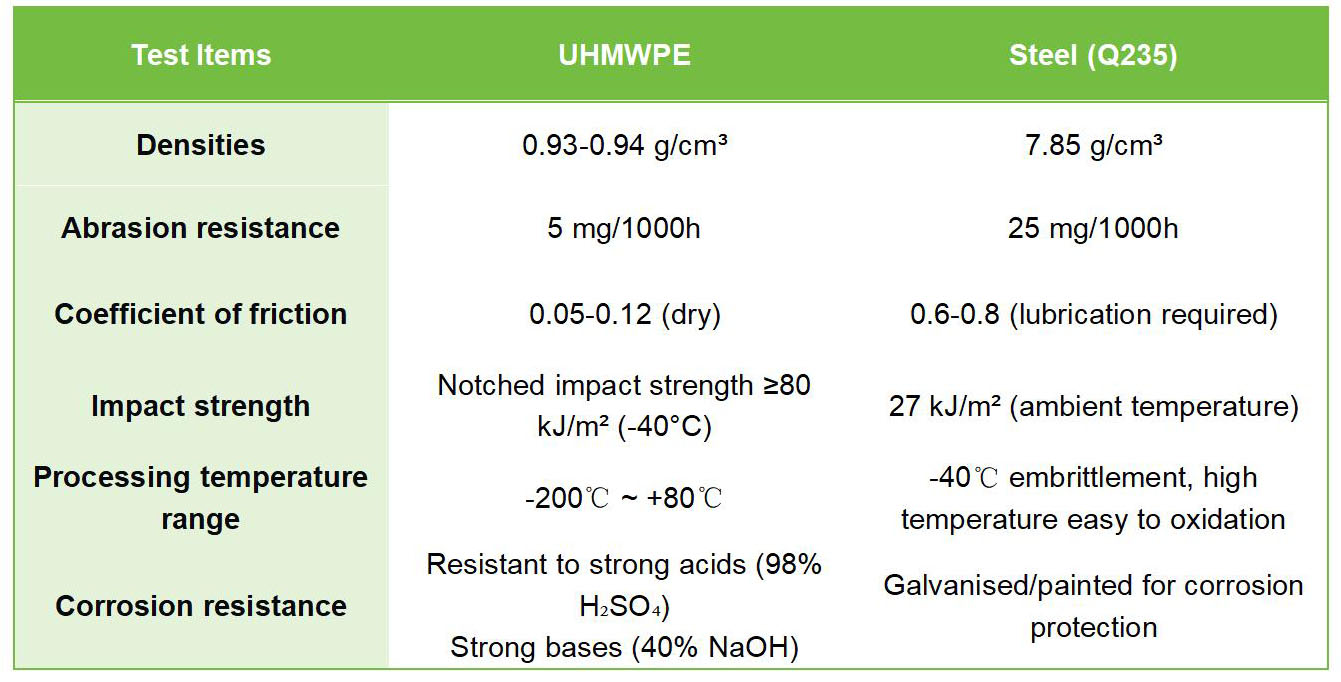

In industrial applications, the choice of material depends on a balance between performance, cost and durability. Traditionally, steel has dominated areas such as construction and machinery, while UHMWPE is emerging as a superior alternative. Below is a comparison of the properties of UHMWPE and steel.

Based on this table it is possible to explain why UHMWPE is now the material of choice for many industries.

Steel is prone to embrittlement under sudden stress, with the potential for catastrophic failure. UHMWPE, on the other hand, absorbs impact more effectively. For example, in mining equipment, UHMWPE liner sheet the impact of falling rocks, reducing downtime and maintenance costs. Unlike steel, UHMWPE is flexible and resists splintering, whereas steel can crack or deform under high impact.

Due to the difference in density, UHMWPE weighs far less than steel in the same dimensions, so in the aerospace sector, UHMWPE can replace steel components in aircraft interiors, improving fuel efficiency and reducing transport and operational energy costs without sacrificing strength. In addition, because steel is much denser than UHMWPE, the use of steel components becomes more complex, requiring additional machinery and more labour to assist in their installation.

Steel corrodes easily when in contact with moisture, chemicals or salt. In contrast, UHMWPE is inherently corrosion resistant. In marine applications, UHMWPE fenders outperform steel in salt water, preventing rust and extending service life. This eliminates the need for expensive coatings and maintenance.

Although UHMWPE has a higher upfront price, its durability reduces life cycle costs. A study in the automotive industry showed that UHMWPE bumpers last longer than steel bumpers, reducing repair and replacement costs by 50 per cent. Its lower maintenance requirements further reduce overheads.

In summary, UHMWPE outperforms steel in the areas of abrasion and corrosion resistance, lightweighting, etc. Despite the higher initial cost, UHMWPE significantly reduces the total cost of ownership over the long term, especially in scenarios of high abrasion and corrosion, and where weight reduction is required.

Previous: What Are the Best Ground Protection Mats for Heavy Equipment? Next: HDPE Sandwich Sheet vs PVC Foam Board

ODM & OEM

UHMWPE, HDPE, PP, Nylon, ABS and any Material

Customized Packaging

Graphic customization

Size & Color custom