Peliou New Materials Technology Co.,LTD

Peliou can not only produce high-quality products, our biggest advantage is that we can customize according to the needs of customers. Today, we will talk about the custom process of logo.

Peliou can not only produce high-quality products, our biggest advantage is that we can customize according to the needs of customers. Today, we will talk about the custom process of logo. There are three different processes for logo customization: sticker, screen printing and laser printing. We will give you a detailed explanation of each different process in turn so that you can have a deeper understanding of logo customization.

The first form of customization is stickers. This is the most traditional way to display a logo. The advantage of using stickers is that they are cheap and can be implemented in any color or shape you want. The disadvantages are also obvious, because of the use of the paste way, its fastness and durability is some problems. It may not be a problem in the short term, but for some products, like chopping boards. Because cutting boards come into constant contact with water, they may fall off after a few years of use.

The second method of customization is screen printing. This way is through the silk screen, will want to print the pattern hollowing out on the silk screen, and then use special ink, to apply a certain pressure on the printing product, so as to achieve printing. Screen printing features advantages in the price between sticker and laser printing, and the use of special ink durability, can be used for several years without fading. Disadvantages require separate plate making for the printed pattern and special ink.

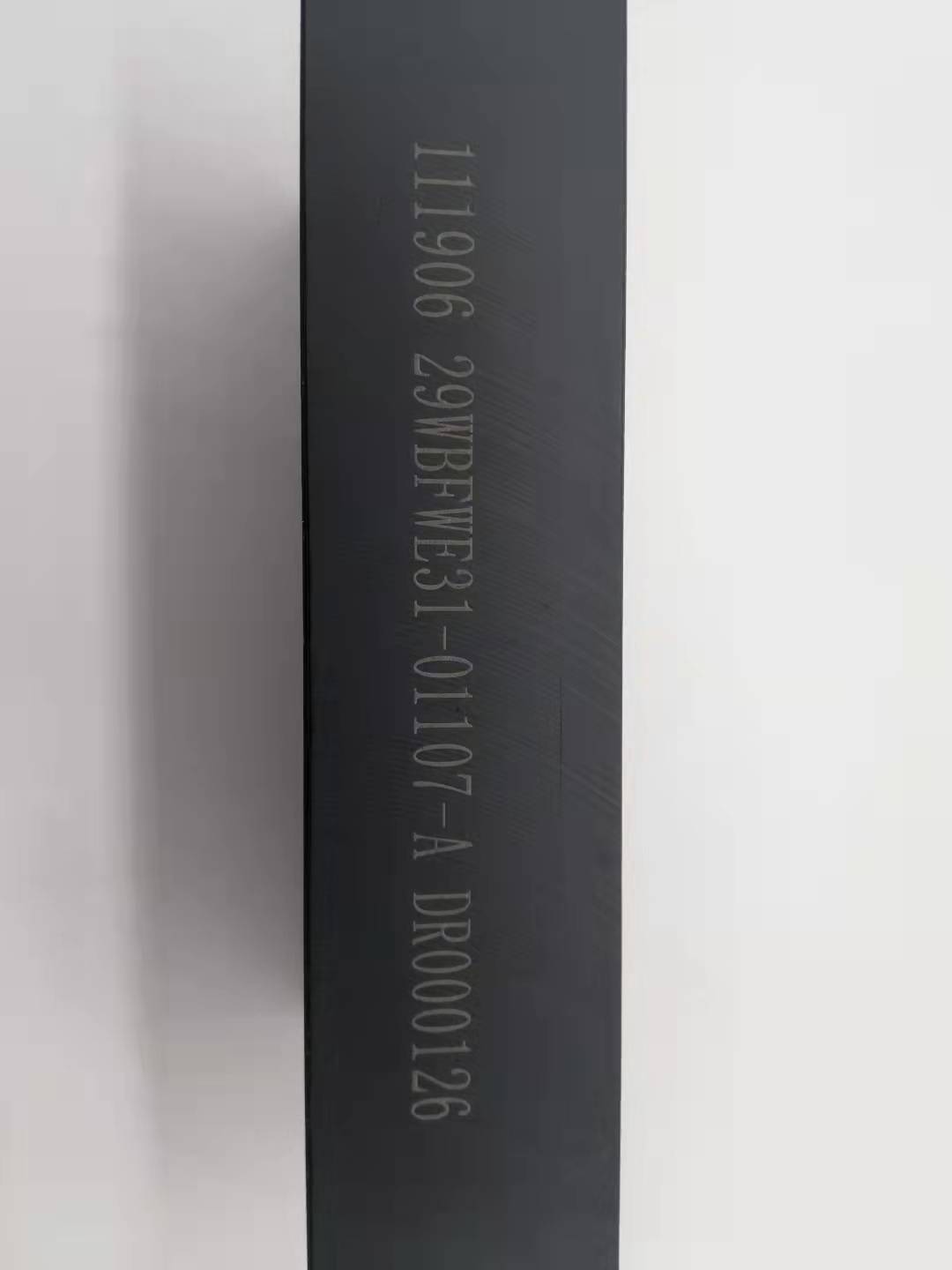

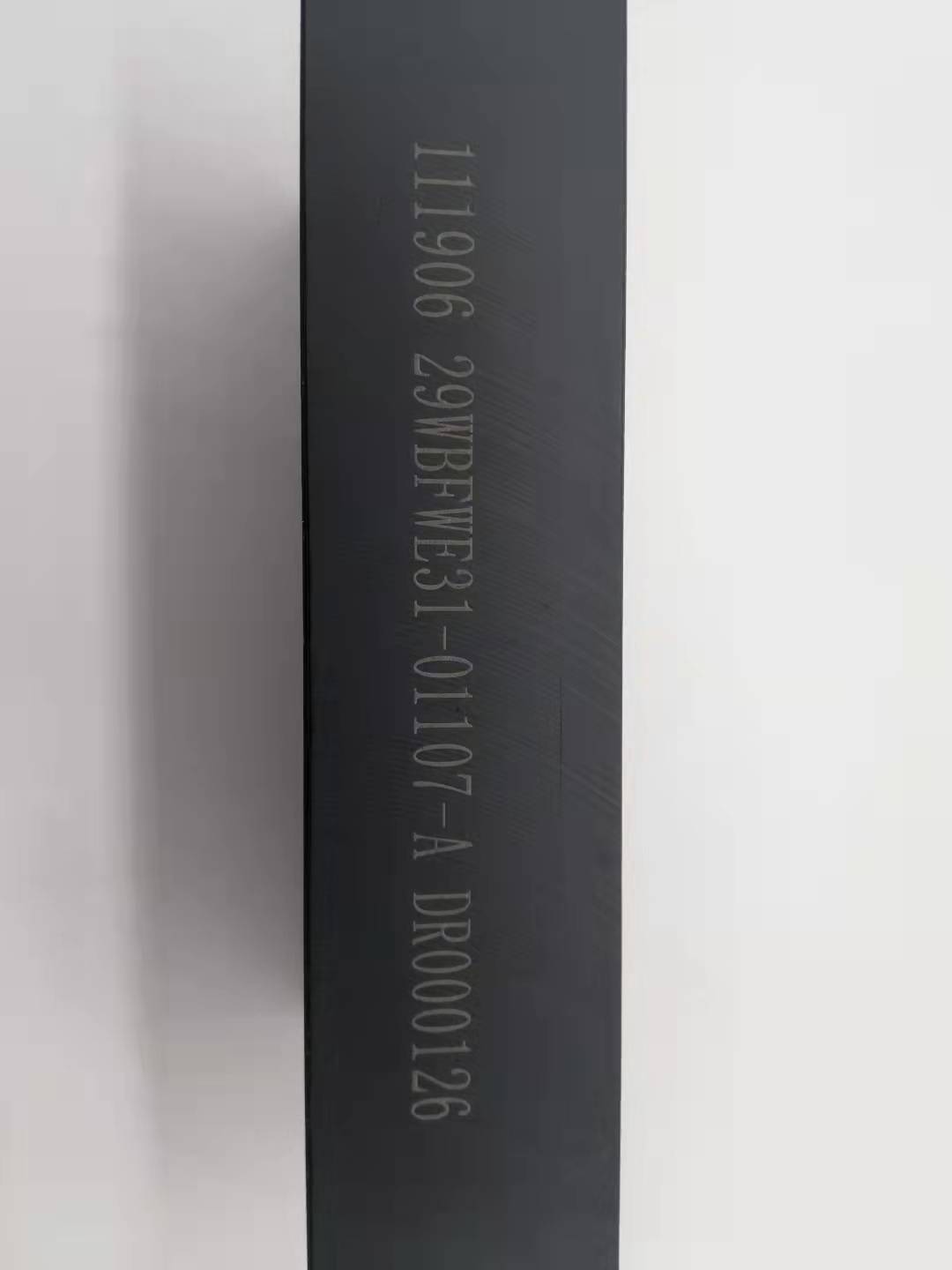

The third type of printing is laser printing. Laser printing is a kind of printing method rising with the progress of science and technology in recent years, which is favored by many customers. The biggest advantage of laser printing is durability. Stickers fall off and silkscreen ink fades, but laser-printed patterns and fonts remain the same forever. Secondly, the pattern shape of laser printing has a high degree of freedom, and the printed font can be hollow or solid. Of course, is laser printing perfect? Not so. The disadvantage of laser printing is that it is more expensive, compared to sticker and screen printing. Laser printing is also limited to black, or the color of the product itself.

We have introduced three ways, respectively: sticker, screen printing, laser printing. They each have their own characteristics, and no one is better than the other two. Therefore, if you need to customize the pattern, text or logo on the product, or need to choose their own printing mode according to their own needs. That's all for today's news, if you need anything, please contact us directly.

Previous: Let's have an exciting kart race! Next: Wood or Plastic?

ODM & OEM

UHMWPE, HDPE, PP, Nylon, ABS and any Material

Customized Packaging

Graphic customization

Size & Color custom