Peliou New Materials Technology Co.,LTD

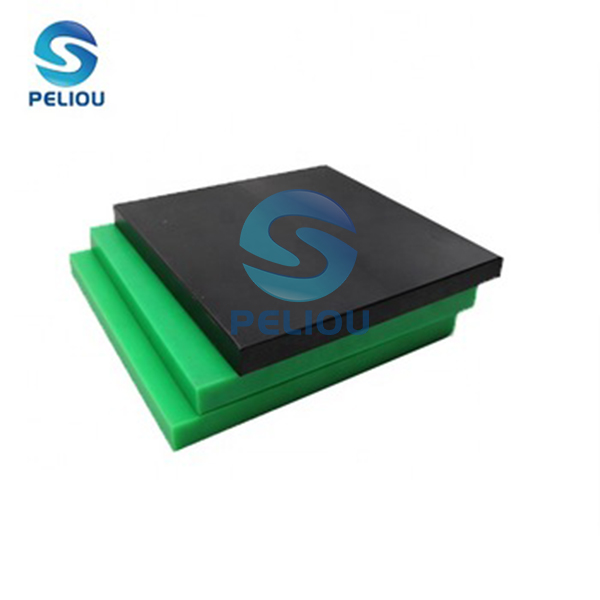

The biggest difference between PE 1000 sheet and ordinary PE sheet lies in their different molecular weights. PE 1000 sheet refers to ultra-high molecular weight polyethylene, while ordinary PE sheet is high-density polyethylene. The molecular weight is d

The biggest difference between pe 1000 sheet and ordinary PE sheet lies in their different molecular weights. PE 1000 sheet refers to ultra-high molecular weight polyethylene, while ordinary PE sheet is high-density polyethylene. The molecular weight is different, so the wear resistance is also different. This difference is to ensure that the pe 1000 sheet has enough strength to achieve the wear resistance and impact resistance that other low-grade polymer products cannot.

PE 1000 sheet technology is becoming more and more mature in china, and more and more projects use this new thermoplastic engineering plastics. Let's take a closer look at the advantages of pe 1000 sheet.

(1) Wear resistance. The wear resistance of pe 1000 sheet is 4-7 times higher than that of ordinary steel plate and 27.3 times higher than that of stainless steel. It is 17.9 times of phenolic resin, 6 times of nylon 6, 4 times of polyethylene, and the average annual wear rate is 0.58 ㎜, which improves the service life.

(2) Impact resistance: among the existing engineering plastics, the impact toughness value of pe 1000 sheet is the highest, and its impact strength at room temperature is more than 10 times that of PE100. With the decrease of ambient temperature, its impact resistance is stronger.

(3) Corrosion resistance: it can resist the corrosion of most corrosive media and organic solvents. PE 1000 sheet can be used in concentrated hydrochloric acid with concentration less than 80%. It is quite stable in sulfuric acid with concentration less than 75% and nitric acid with concentration less than 20%.

(4) Self lubrication, self sliding performance better than oil lubricated steel or brass. In places with harsh environment, dust and sediment, pe 1000 sheet has better dry lubrication performance. It can move freely and protect related workpieces from wear or strain. The friction coefficient is only 0.07~0.12, which is 1/5 of ordinary PE and 1/20 of rubber.

(5) Non toxic, pe 1000 sheet material is a national certified environmental protection material, non-toxic and tasteless, anti pollution and moth resistant new thermoplastic engineering plastic. The US Food and Drug Administration (FDA) and the US Department of Agriculture (USDA) allow it to be used in contact with food and drugs.

(6) Low temperature resistance and aging resistance. PE 1000 sheet can work at - 269 ℃ to 80 ℃ for a long time. Because there are few unsaturated molecular groups in the molecular chain, the molecular weight is large, the stability is high, the aging speed is particularly slow, and the service life is longer.

(7) The surface is non adherent and does not scale. Due to small friction coefficient and non polarity, the pe 1000 sheet is non adherent.

Hebei Peliou is a professional manufacturer of pe 1000 sheet, have rich experience in production and sale of more than 10 years, we can guarantee product quality and stable supply, you can totally trust us, welcome to your inquiry.

Previous: Why choose the PA 6 sheet? Next: Marine grade hdpe board

ODM & OEM

UHMWPE, HDPE, PP, Nylon, ABS and any Material

Customized Packaging

Graphic customization

Size & Color custom