Peliou New Materials Technology Co.,LTD

Looking for high-performance sterilizer retainers? We specialize in ultra-high molecular weight polyethylene sheets—exceptionally wear-resistant, corrosion-resistant, FDA-certified, and clean/sterile. They completely eliminate rusting and jamming issues w

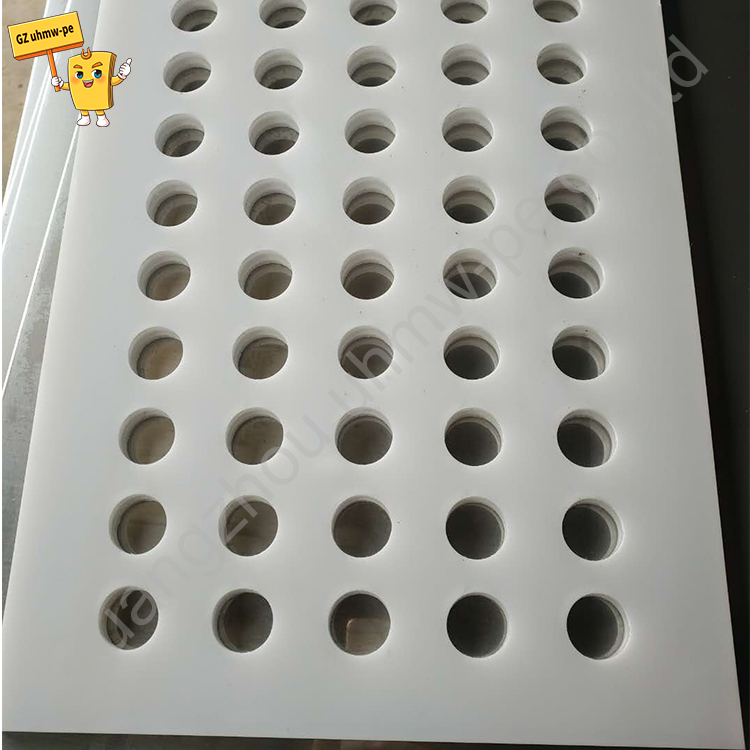

In sterilization processes across food, pharmaceutical, and chemical industries, sterilizer partition plates play a critical role. Traditional metal partitions (such as stainless steel) often face a series of challenges during use, including susceptibility to rust and corrosion, prone to scratching, cumbersome and difficult to operate, and even jamming with the sterilization vessel or baskets. These issues not only impact production efficiency but also pose significant risks of creating hygiene dead zones and contaminating products.

It's time for a complete upgrade! Ultra-high molecular weight polyethylene (UHMWPE) plates, with their exceptional properties, are emerging as the ideal replacement for traditional metal partitions, ushering sterilization processes into a new era of enhanced safety and efficiency.

Why is UHMWPE the perfect solution for sterilizer partition plates?

Ultra-high molecular weight polyethylene is an exceptional engineering plastic with a molecular weight reaching millions, earning it the title “King of Plastics.” When applied to sterilizer partition plates, it demonstrates unparalleled advantages:

1. Exceptional Wear Resistance and Extended Service Life

Core Advantage: Its wear resistance exceeds stainless steel by 8 times and nylon by 5 times. Under frequent loading/unloading and high-pressure steam washing, it minimizes wear debris generation, significantly prolonging the partition's lifespan while protecting sterilization baskets and autoclave interiors—drastically reducing maintenance and replacement costs.

2. Outstanding Corrosion Resistance and Absolute Hygiene Safety

Core Advantage: Exhibits exceptional resistance to chemical corrosive agents including acids, alkalis, and salts, completely eliminating rust issues inherent in metal materials. Its smooth, dense, non-porous surface prevents bacterial and impurity adhesion, facilitates easy cleaning and sterilization, and complies with FDA food contact material standards, providing the highest level of safety assurance for your products.

3. Ultra-Low Friction Coefficient and Smooth Operation

Core Advantage: Features an extremely low surface friction coefficient with outstanding self-lubricating properties. This ensures seamless insertion and removal of partitions without jamming against sterilization baskets or pot bodies, significantly reducing labor intensity, enhancing loading/unloading efficiency, and eliminating equipment damage caused by forced prying.

4. Superior Impact Resistance and High Strength

Core Advantage: Impact strength exceeds ABS by over 5 times, maintaining exceptional toughness even in low-temperature environments. Resists fracture and deformation under heavy impacts or collisions, ensuring stability and reliability in demanding conditions.

5. Lightweight, High-Strength, Energy-Efficient, and Eco-Friendly

Core Advantage: Significantly lower density than metal enables lightweight construction, allowing single-person operation. This reduces labor intensity while lowering overall equipment load, indirectly achieving energy savings.

Wide-ranging Applications Delivering Solutions Across Industries

Our UHMWPE sterilizer pot partitions are extensively used in:

Food Industry: High-temperature, high-pressure sterilization for canned goods, beverages, dairy products, meat products, condiments, etc.

Pharmaceutical Industry: Sterilization of pharmaceuticals and medical devices.

Chemical Industry: Processing of materials requiring corrosion resistance and high-temperature cooking.

Choose Us for Value Beyond Products

We are not just material suppliers but your production challenge solvers.

Rigorous Material Selection: Utilizing premium raw materials to ensure stable performance, purity, and odor-free panels.

Precision Customization: Tailored cutting and drilling according to your sterilizer model and dimensions, delivering perfectly customized partitions.

Expert Technical Support: Our seasoned team provides full-process technical consultation from selection to installation.

Take action now to upgrade your sterilization equipment!

Don't let traditional metal partitions hold back your production line. Choosing high-performance UHMWPE partitions is a strategic investment in product quality, production efficiency, and operational cost reduction.

Click to contact us for a customized solution and sample trial information. Experience firsthand the transformation brought by advanced materials!

Previous: Back List Next: UHMWPE Bottle Flipper: Designed for Efficiency and Safety

ODM & OEM

UHMWPE, HDPE, PP, Nylon, ABS and any Material

Customized Packaging

Graphic customization

Size & Color custom