Peliou New Materials Technology Co.,LTD

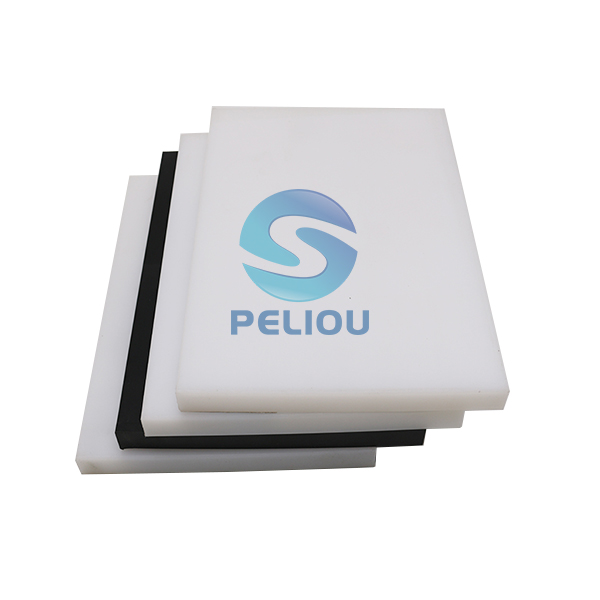

Ultra-high molecular weight polyethylene sheet and high-density polyethylene sheet can be distinguished from the following aspects1. Molecular weight:The molecu

Ultra-high molecular weight polyethylene sheet and high-density polyethylene sheet can be distinguished from the following aspects

1. Molecular weight:

The molecular weight of UHMWPE is usually in the range of millions to tens of millions, while that of HDPE is usually in the range of tens of thousands to hundreds of thousands.The high molecular weight of UHMWPE gives it better physical and chemical properties.

2. Abrasion resistance

UHMWPE has excellent abrasion resistance and is commonly used in highly abrasive environments such as conveyor belts and liners. HDPE has some abrasion resistance, but not as much as UHMWPE.

3. Impact strength:

The impact strength of UHMWPE is very high and can withstand heavy impacts and shocks, making it suitable for high-impact applications, while the impact strength of HDPE is relatively low.

4. Temperature resistance:

UHMWPE's high temperature resistance is relatively poor, generally used below 80°C, while HDPE's temperature resistance can reach about 130°C.

5.Processability:

HDPE is easy to process and suitable for injection and extrusion moulding, while UHMWPE is relatively difficult to process and usually requires special equipment and technology.

Different application scenarios for the two types of sheets

UHMWPE sheet

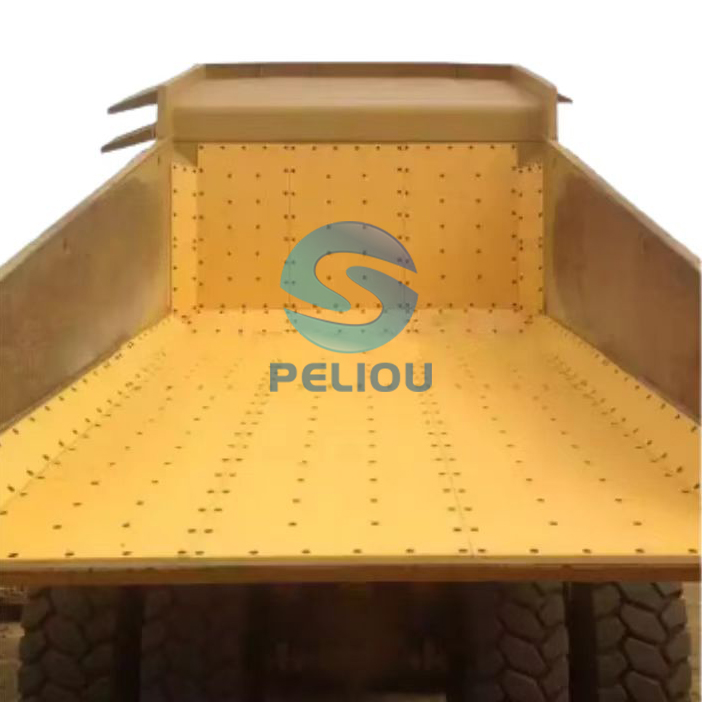

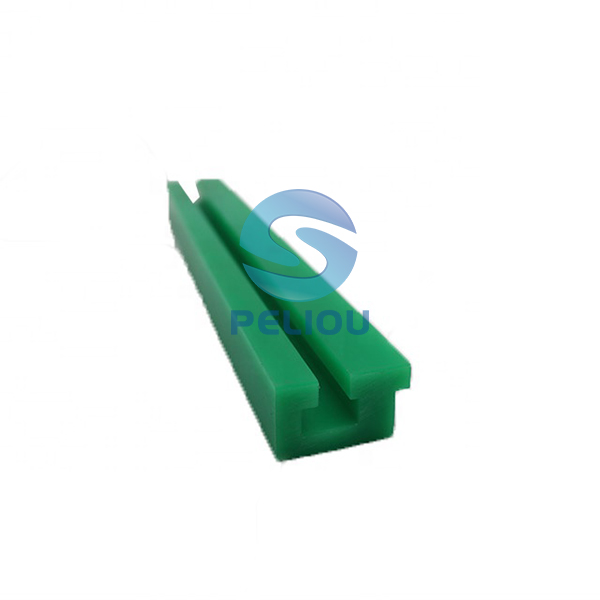

Guide wear strips: used in highly abrasive environments such as mining and grain processing.

Liners and protective materials: used for liners in mining equipment, hoppers and chutes, providing excellent wear resistance.

Medical devices: commonly used in surgical instruments and prosthetics due to their excellent biocompatibility.

Ships and harbours: protective material for ships to reduce collision damage.

Food processing: used for parts of food processing equipment, as it is less susceptible to contamination and easier to clean.

High Density Polyethylene Sheet

Packaging and Containers: widely used in the manufacture of various plastic containers and packaging materials.

Piping: Used for drainage and water supply pipes due to its good corrosion resistance.

Building materials: used as building partitions, siding and waterproofing materials.

Agricultural applications: such as greenhouse covers and agricultural films due to its UV resistance.

Toys and Household Products: Used in the manufacture of safe toys and household products due to its non-toxicity and durability.

Previous: What is a soccer rebounder used for? Next: What is an HDPE board used for?

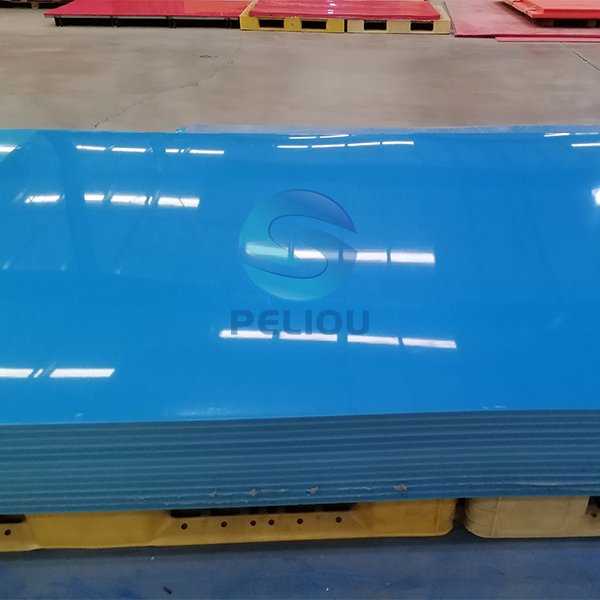

ODM & OEM

UHMWPE, HDPE, PP, Nylon, ABS and any Material

Customized Packaging

Graphic customization

Size & Color custom