Peliou New Materials Technology Co.,LTD

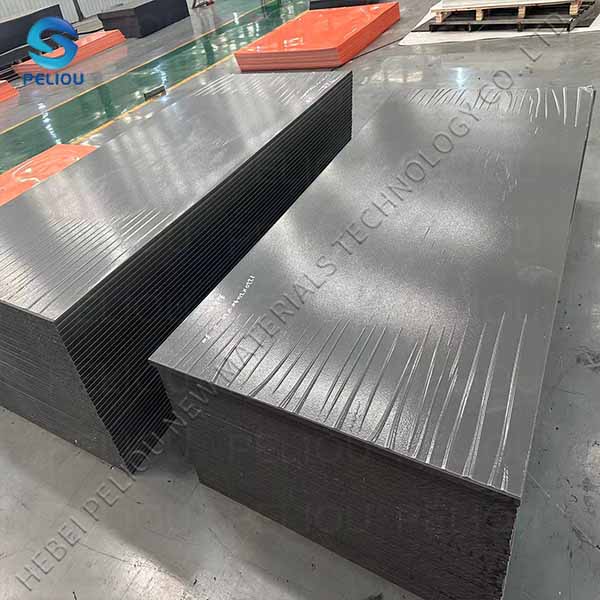

In industrial and construction applications, polypropylene (PP) plastic sheets are widely used for their durability, chemical resistance, and versatility. However, the use of low-quality PP sheets—including PP textured sheets, PP sheets for tanks, and sol

Substandard PP plastic sheets often lack the structural integrity required for demanding environments. For instance, PP sheets for tanks made from poor-quality materials can crack or warp when exposed to chemicals, risking leaks and environmental contamination.

Low-grade solid polypropylene sheets may also fail to meet fire-retardant or thermal stability standards, increasing the risk of workplace hazards. Furthermore, cheap PP materials often contain harmful additives that release toxic fumes when heated, endangering worker health.

How to Choose High-Quality PP Plastic Sheets

1.Verify Material Certifications

Reputable PP sheet manufacturers provide certifications (e.g., ISO, FDA, or UL listings) confirming compliance with industry standards. For specialized applications like PP sheets for tanks or solid polypropylene sheets, ensure the material meets chemical resistance and thermal stability requirements.

2.Assess Application-Specific Needs

Match the sheet type to its intended use. For example, PP textured sheets are ideal for slip-resistant flooring, while heavy-duty PP plastic sheets may be required for structural components. Clarify load-bearing capacity, UV resistance, and temperature tolerance with your supplier.

3.Inspect Physical Properties

High-quality PP sheets should have uniform thickness, smooth edges, and no visible defects like bubbles or cracks. Test samples for flexibility and impact resistance—substandard sheets may snap or warp under stress.

4.Prioritize Reputable Manufacturers

Partner with established PP sheet manufacturers known for transparency and quality control. Request material datasheets detailing density, tensile strength, and additive composition. Avoid suppliers unable to provide traceability or technical support.

Previous: UHMWPE Sheet: The Ultimate Polymer Solution for Demanding Industrial Applications Next: PP Material Plastic Sedimentation Tanks: The Smarter Choice for Industrial Efficiency

ODM & OEM

UHMWPE, HDPE, PP, Nylon, ABS and any Material

Customized Packaging

Graphic customization

Size & Color custom