Peliou New Materials Technology Co.,LTD

When operating cranes, ensuring stability is non-negotiable. A critical component of this process is selecting and sizing crane outrigger pads correctly. These pads distribute the crane’s load across a larger surface area, preventing ground failure and ti

Crane Weight and Load Capacity

The combined weight of the crane and its load determines the pressure exerted on the ground. Heavier loads require larger or thicker outrigger pads to spread the force effectively. Always consult the crane manufacturer’s specifications for load limits.

Ground Conditions

Soft or uneven terrain (e.g., soil, gravel, or asphalt) demands larger pads to reduce ground pressure. For unstable surfaces, consider using layered truck outrigger pads or combining multiple pads for added stability.

Pad Material

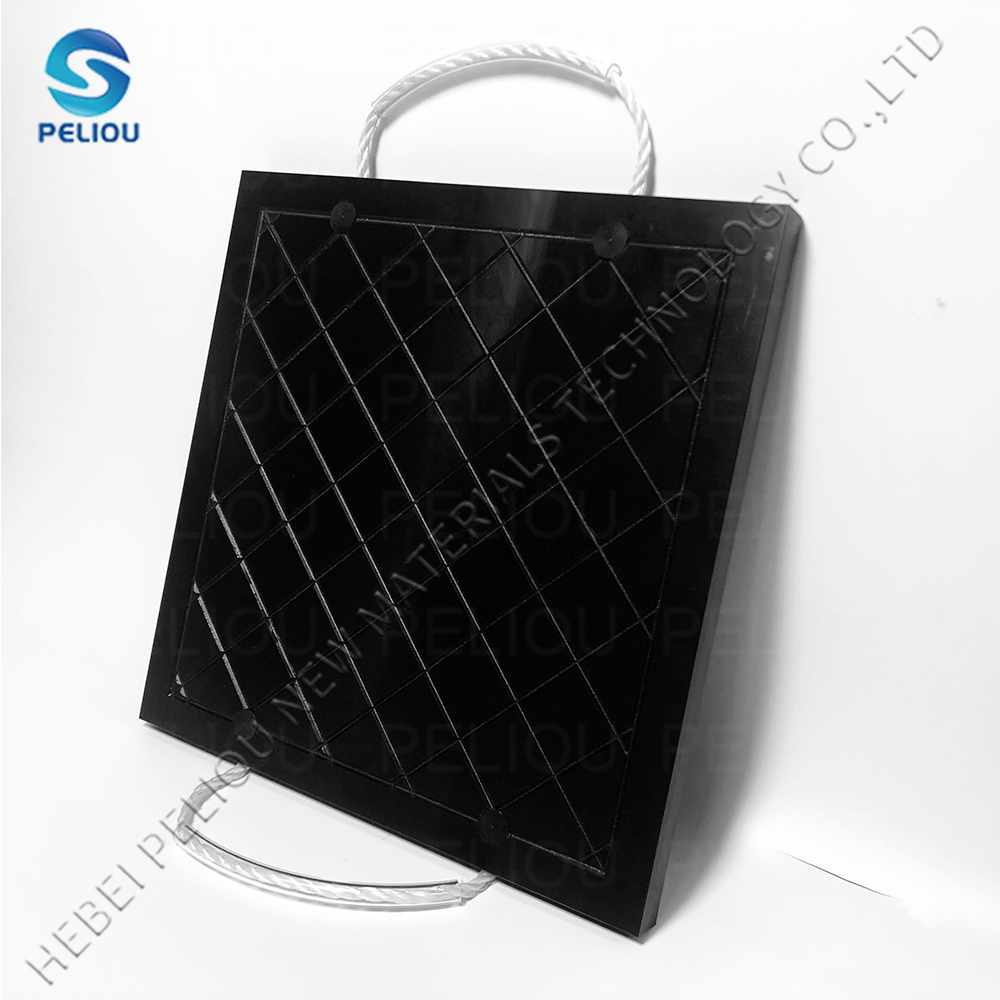

Material choice impacts performance. Standard pads are often made from steel or hardwood, but advanced options like Uhmwpe crane outrigger pads (Ultra-High Molecular Weight Polyethylene) offer superior durability, lightweight handling, and resistance to moisture and chemicals.

Calculate Required Surface Area

Use the formula:

For example, if the total weight is 100,000 lbs and the ground capacity is 2,000 psf, the minimum pad area should be 50 sq ft.

Factor in Safety Margins

Always add a 20-30% safety buffer to account for dynamic forces, uneven weight distribution, or unexpected ground shifts.

Choose the Right Material

For heavy-duty applications, Uhmwpe crane outrigger pads are ideal due to their high strength-to-weight ratio. They’re also easier to transport and position compared to steel pads.

Test and Adjust

Conduct a ground pressure test before full operation. If the pad sinks or shifts, increase the size or add secondary support.

Ignoring Ground Variability: Always assess the worksite—what works on concrete may fail on wet soil.

Underestimating Load Dynamics: Wind, motion, and load shifts increase pressure. Oversize pads when in doubt.

Using Worn or Damaged Pads: Inspect crane outrigger pads regularly for cracks or deformation.

Properly sized outrigger pads are a small investment with massive returns in safety and productivity. For demanding environments, prioritize innovative solutions like Uhmwpe crane outrigger pads to maximize stability without compromising mobility. By combining precise calculations, material expertise, and site-specific adjustments, you can ensure your crane operations remain safe and efficient.

Always consult engineering professionals when working with complex loads or challenging terrains.

Previous: How Well Does Marine HDPE Sheet Hold Up to Marine Environment? Next: Celebrate the Heart of Progress: Happy International Workers' Day!

ODM & OEM

UHMWPE, HDPE, PP, Nylon, ABS and any Material

Customized Packaging

Graphic customization

Size & Color custom