Peliou New Materials Technology Co.,LTD

Marine environments pose unique challenges for materials, from relentless UV exposure to saltwater corrosion and biological growth. Among modern solutions, marine HDPE sheet has emerged as a durable and versatile choice for marine applications.

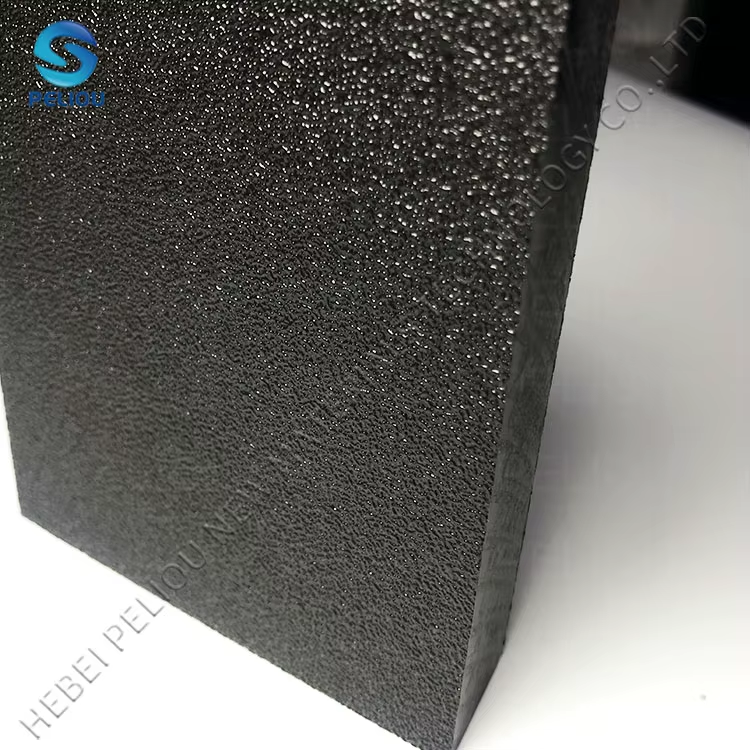

Marine grade HDPE board is engineered specifically to withstand harsh oceanic conditions. High-density polyethylene (HDPE) boasts exceptional resistance to saltwater, chemicals, and UV radiation, preventing degradation over time. Unlike traditional materials like wood or metal, HDPE does not rot, rust, or require frequent maintenance. This makes it ideal for docks, boat components, and seawall installations.

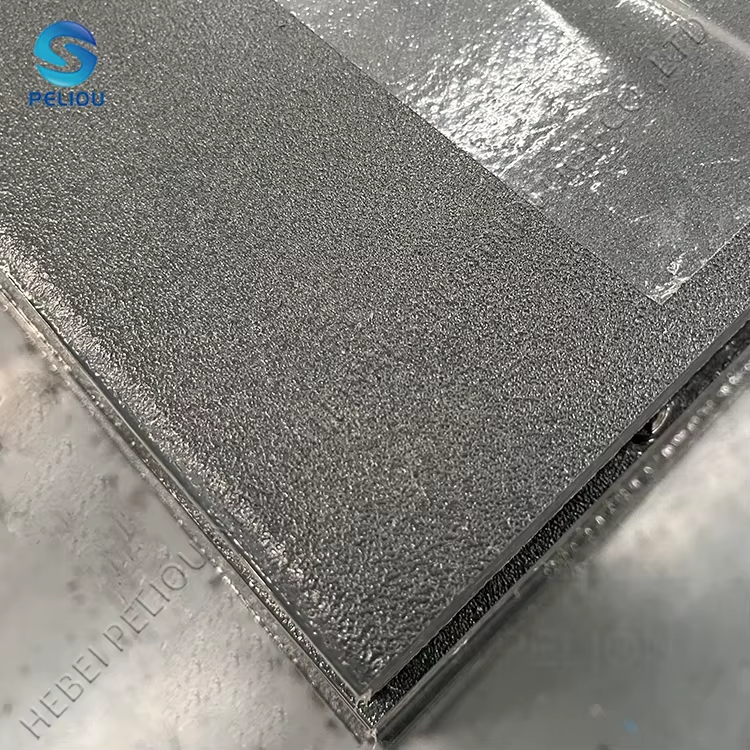

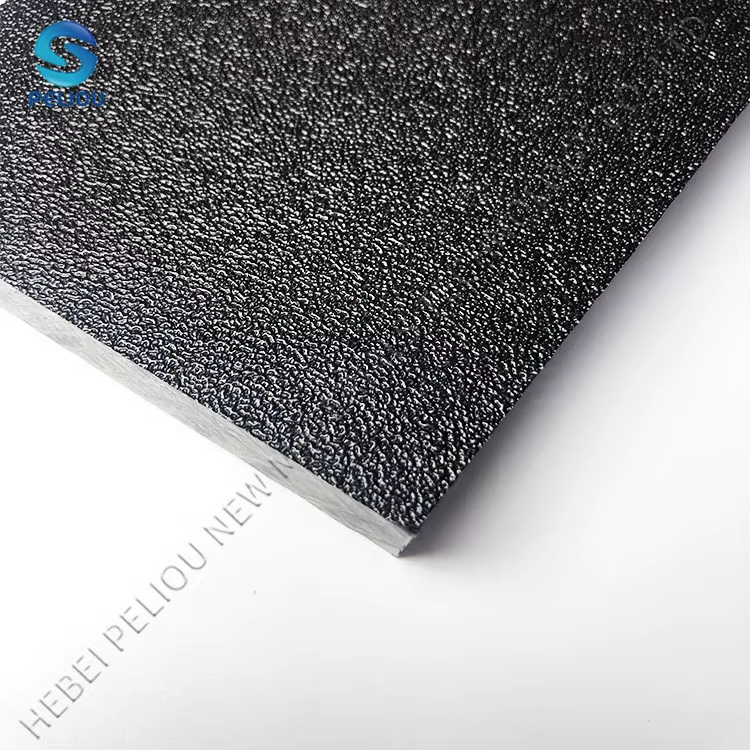

A popular variant, textured HDPE sheet, adds functionality with its non-slip surface. This feature is critical for marine decks, ramps, and platforms where safety is paramount. The texture enhances grip without compromising the material’s innate resistance to moisture or mold.

When comparing options, Starboard HDPE sheet stands out as a branded marine-grade product known for its reliability. Widely used in boatbuilding and marine fixtures, Starboard combines HDPE’s durability with precise manufacturing standards, ensuring longevity even in extreme conditions.

Applications for marine HDPE sheet extend beyond structural uses. Its lightweight yet robust nature makes it suitable for hatches, trim, and seating. Additionally, its resistance to barnacles and algae reduces the need for antifouling treatments, lowering long-term costs.

In summary, marine-grade HDPE products like textured sheets and Starboard offer a blend of resilience, safety, and low maintenance. Whether for commercial or recreational marine projects, these materials deliver performance that traditional alternatives struggle to match—proving that innovation can indeed stand the test of the sea.

Previous: PP Material Plastic Sedimentation Tanks: The Smarter Choice for Industrial Efficiency Next: How to Correctly Size Outrigger Pad for Maximum Stability

ODM & OEM

UHMWPE, HDPE, PP, Nylon, ABS and any Material

Customized Packaging

Graphic customization

Size & Color custom